New Bank of England cooling system delivers dramatic savings in energy and carbon emissions

A £6.5m project to replace long-serving chillers and related plant at the Bank of England has resulted in a state-of-the-art installation, with outstanding resilience and dramatic reductions in energy consumption, running costs and carbon emissions.

The two-year project involved replacing three ageing centrifugal chillers and two reciprocating chillers cooling the building and critical infrastructure (with a combined capacity of 4.2MW), and installation of new high efficiency variable speed Carrier chillers (with an enhanced capacity of 5.8MW). Despite increased intensity of use, energy savings following the project are estimated at around £3000 a week.

Alongside the installation of new high efficiency chillers, the project involved replacing six roof-top cooling towers, four for chilled water and two for the Bank’s stand-by generators, and replacement of a 11kV/3.3kV electrical sub-station supplying the chillers.Motors and drives in the building’s main and secondary air handling units were also upgraded. On the controls side, the existing Building Management System (BMS) was enhanced, to provide better monitoring and analysis capability.

Alongside the installation of new high efficiency chillers, the project involved replacing six roof-top cooling towers, four for chilled water and two for the Bank’s stand-by generators, and replacement of a 11kV/3.3kV electrical sub-station supplying the chillers.Motors and drives in the building’s main and secondary air handling units were also upgraded. On the controls side, the existing Building Management System (BMS) was enhanced, to provide better monitoring and analysis capability.

AECOM was commissioned to produce a detailed performance specification for the chiller replacement and related works, which the main contractor, Interserve Engineering Services, then carried forward as the basis for the chiller and other equipment supply tenders.

Crucially, the design was based on a N+1 redundancy approach in relation to the critical cooling load, which includes the Bank’s data centre facility, considered to be of national importance.

Crucially, the design was based on a N+1 redundancy approach in relation to the critical cooling load, which includes the Bank’s data centre facility, considered to be of national importance.

Five manufacturers competed for the chiller contract, and after a detailed evaluation Carrier was awarded the tender to supply four chillers on the basis of value, class-leading energy efficiency, engineering quality and proven ability to meet project deadlines.

A key challenge for the team was to deliver the project while the iconic Grade One building in the heart of the City of London continued to function as normal, with full occupancy, without any interruption of cooling to the building or vital services.

“It is akin to servicing a jet airliner whilst in flight,” says Robert Foster, head of the Bank of England’s Operations and Maintenance department, who was responsible for the project. “Work on the progressive project had to be carefully managed over the 24-month changeover period to ensure continuity of cooling throughout. Due to its scale and importance for the Bank’s operations, it was a major undertaking requiring a high degree of planning collaboration and close working between all the parties.”

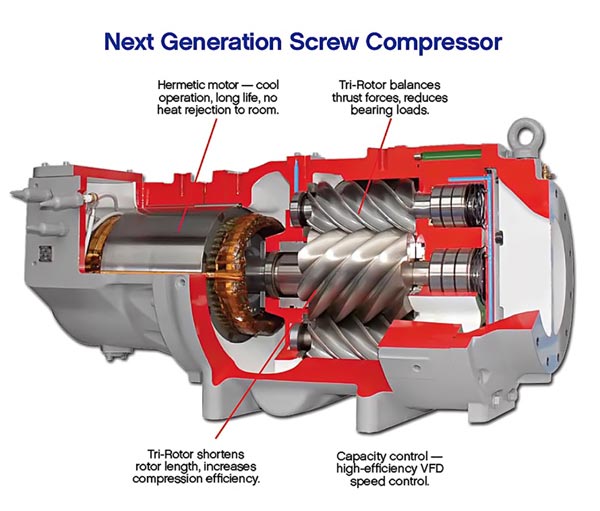

One of the new chillers is a Carrier® AquaEdge™ 23XRV water-cooled screw chiller. Equipped with a variable speed drive and hermetic motors, it is claimed to be one of most efficient chillers on the market. At the time the order was placed, the AquaEdge was only being manufactured in the US, therefore a US-built unit was shipped for installation at the Bank.

One of the new chillers is a Carrier® AquaEdge™ 23XRV water-cooled screw chiller. Equipped with a variable speed drive and hermetic motors, it is claimed to be one of most efficient chillers on the market. At the time the order was placed, the AquaEdge was only being manufactured in the US, therefore a US-built unit was shipped for installation at the Bank.

The variable speed chiller has the ability to adjust compressor speed in fine increments, optimising operation in relation to ambient conditions and load. It enables the chiller to precisely match cooling output to building load, thereby conserving energy.

The unit provides cooling for the building’s base load. Given its exceptional efficiency, this means that a substantial proportion of the Bank’s cooling load is delivered by the most efficient available means. A secondary benefit of the variable speed chiller is its built-in soft-start, ensuring low current draw and low noise upon start-up.

Two of the other new chillers are water-cooled Carrier AquaForce® 30XW units, based on twin rotor screw compressors, assigned to provide additional cooling on top of the base load, providing both head room for expansion and the required resilience. The fourth chiller, a smaller Carrier AquaForce® 30XW1052 unit, is the lead chiller during the winter months. Heat is recovered from the chiller to supply the low temperature panel heating system throughout the Bank.

The controls philosophy was an important part of the design, the aim being to even-out chiller run-time to help reliability and minimise power use. At its heart is a Sauter Building Management System which sequences the chillers according to building load and ensures system resilience, via redundancy. The complete system is fully integrated and visualised across the Bank’s BMS network.

Ensuring effective communications between all parts of the system proved to be one of the most technically complex aspects of the project. An initial problem stemmed from different routing protocols between the US and European manufactured plant. However, the team traced the source of the problem and established full communications.

The new system wherever possible makes use of existing headers and chilled water circuits. However, the project was made more complex due to the logistical challenge presented by the underground plant room and sub-station. The physical structure of the 1930s building meant that access was severely restricted.

The underground plant room is a bit like a ship’s hold,” says Robert Foster. “There is a hydraulic lift for access, but the space is restricted and difficult to operate in, particularly given the size of the equipment requiring removal and replacement.”

The underground plant room is a bit like a ship’s hold,” says Robert Foster. “There is a hydraulic lift for access, but the space is restricted and difficult to operate in, particularly given the size of the equipment requiring removal and replacement.”

To manage this, the project required a 16-phase sequencing strategy, covering all steps needed to prepare for decommissioning and removal of existing cooling plant, and installation of the new chillers and cooling towers, controls, pumps and power systems. Hot tapping and line stopping of the existing system plus installation of temporary headers was essential to ensure an uninterrupted chilled water supply throughout the project.

The work involved roof access using cranes, which required road closures. A unique consideration impacting deliveries of plant and materials was the unannounced arrival (for security reasons) at the Bank of deliveries of bullion and cash. On occasion, this necessitated items being placed in temporary store offsite, until onsite access was restored.

Existing chillers were decommissioned and removed in a staged process, and new replacement chillers – dismantled into four sections – positioned in place. In disassembling the chillers, Carrier ensured that refrigerant circuits were retained intact, to ensure the factory-finished integrity of the system. Once elements were in place within the plant room, they were reassembled and replacement chillers connected up and commissioned.

Mr Foster, who also manages the Bank’s utility budget, says that reducing energy costs and related carbon emissions was a key driver. “We wanted to ensure that not only was resilience enhanced, but power consumption and ongoing running costs were significantly reduced. We have a responsibility both to the environment and society at large to minimise the environmental impact of our buildings and reduce expenditure on energy. The result of the project is a win-win for both.”

A three-pronged approach to energy reduction was used. The elements are: reduction of demand through improved design and building use; improved efficiency due to new and upgraded plant and equipment; and improved management due to better monitoring and control.

The result is an estimated 48 per cent saving on cooling energy, which translates into a saving of some £150,000 a year, and £3m over the 20-year design lifetime of the chiller plant. This has reduced the Bank’s carbon emissions by 717tonnes of CO2 equivalent per year, representing an 8per cent reduction in overall emissions.

The Bank displays its DECC energy efficiency certificate prominently in its reception lobby. As a result of the chiller upgrade and other related building services improvements, its energy efficiency rating has been improved by one full band.

Despite the complexity and unique challenges, the two year project was delivered on time and within-budget. The plant room is now state-of-the-art in terms of technology, resilience and energy efficiency.

The Bank has confirmed that the Carrier chillers at the heart of the project have performed well against the high design specification. They are now realising the savings from the efficiency improvements, which will obviously continue to accrue over the lifetime of the plant, despite the increase in intensity of building use.

The success of the project is testimony to careful planning and the excellent working partnerships between the Bank and its suppliers.

The Bank continually reviews and upgrades its engineering infrastructure, striving towards best practice in terms of replacing end-of-life plant with best available technology, whilst taking advantage of energy saving opportunities and reducing its carbon footprint where possible.